Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: GT4-12A

Brand: Borong

Machinable Material: Carbon Steel

Old And New: New

Place Of Origin: China

Degree Of Automation: Automatic

Certification: Iso 9001:2000

Warranty Period: 1 Year

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Core Selling Point: Long Service Life

Applicable Industry: Construction Works

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Marketing Type: Ordinary Product

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Core Component Warranty Period: 1 Year

Power: 5.5kw

Weight: 340kg

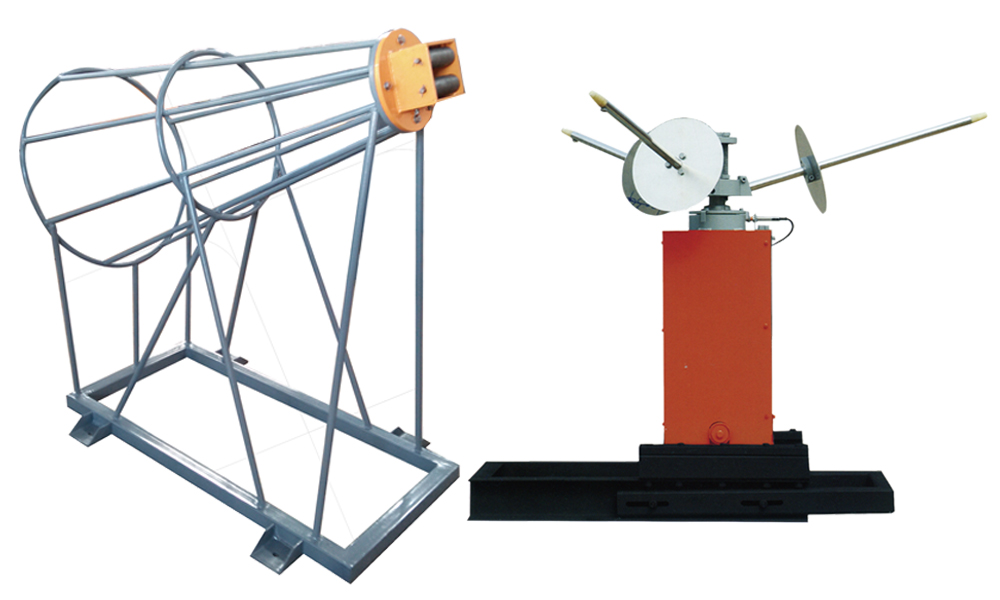

Type: Cnc Bending Machine

Voltage: 380v,customizable

Motor Speed: 1440r/ Min

Round Bar: 4-12mm

Rebar: 4-10mm

Straightening Speed: 35-50m/Min

Cutting Length: 0.3-99m

Cutting Error: ±5

Dimension: 160 *68 *95cm

Packaging: Wooden box

Productivity: 100 sets per month

Transportation: Ocean

Place of Origin: HeBei of China

Supply Ability: 100 sets per month

Port: Tianjin

Payment Type: T/T,Paypal

Incoterm: FOB,CFR,CIF,EXW

Features:

· This rebar stirrup hooking bending machine steel adopts servo controlling system;

· Automatically accomplish the functions of rebar's feeding, straighten, bending and cutting etc.;

· Biggest bending diameter of rebar is 12mm;

· Continuously bend various stirrup of plane figure;

· Widely used in construction industry and rebar manufacturing enterprise;

· High efficiency and accurate processing precision.

Advantages:

1. Mechanical cut, more stable, no failure ,Not affected by the weather, bending fast.

2. Main frame material is 10*10 square steel; National standard; High stability

3. More wheels on the Straighten plate, good effect

4.Feeding device is box structure, stable wire feeding, high speed, high precision

5. Can choose forward and reverse bending

6. Free air pump (air compressor)

7. Variety of species for choose. High-end, mid-range, low-end.

Motors brand: ALPHA

Controller brand : Kinco

Electircal Components brand: CHAT and DELIXI

Product parameters

| Single bar diameter(mm) | 4-13 |

| Double bar diameter(mm) | 4-10 |

| Biggest bending angle | 180 |

| Biggest towing speed(m/min) | 130 |

| Biggest bending speed | 1460 |

| Angular accuracy | 1 |

| Power(KW) | 21 |

| Shape processing(kinds) | 150 |

| Working temperature(℃) | -5-40 |

| Weight(kg) | 2000 |

| Dimension(mm) | 3800*1100*1700 |

| Average power(KW/h) | 28Kw |

As a professional machinery manufacturer, we do have different kinds of construction machinery. Thread Rolling Machine For Sale, contact me if you need it. We will offer you a reasonable Roll Thread Machine Price and best Thread Rolling Services. Besides this Z28-80, we do have Z28-200 Type Thread Rolling Machine, they are both High Speed Thread Rolling Machine. Also we have Steel Straightening Machine, Rebar Bending Hoop Machine, Hydraulic Concrete Converying Transport Pump, and so on. The most important, it can be customized according to various needs.

Product Categories : Rebar Mechanical Equipment > Automatic CNC Steel Bending Hoop Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.